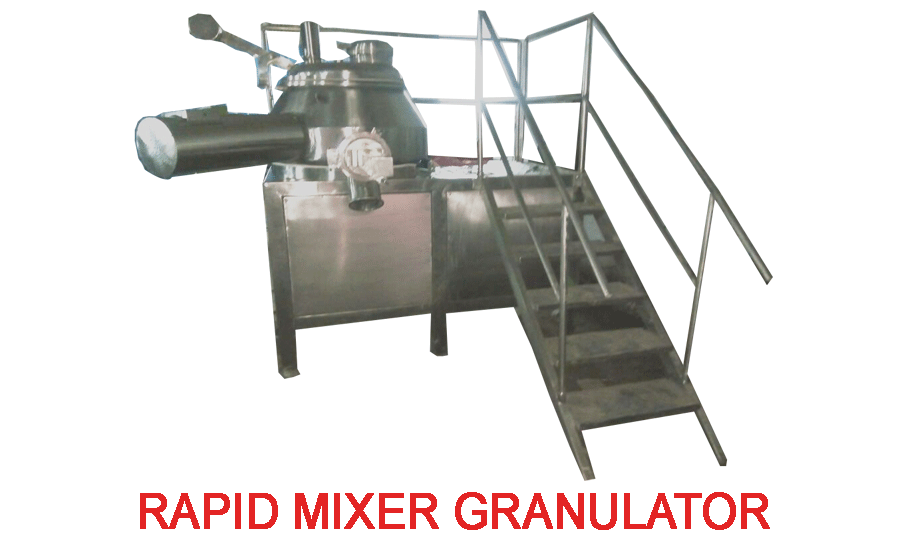

RAPID MIXER GRANULATOR

Application

"KPM PHARMA" The Rapid Mixer Granulator used for process of fast dry & wet mixing, homogenizing, humidifying and granulating of the powder in Pharmaceutical, Chemical, Cosmetic, Food, General Mixing Industries.

Process

The Rapid Mixer Granulator performs dry mixing & wet granulating by basic design of the special four arm of the mixing impeller and sequences of the mixing process in the cylindrical mixing drum with rounded connection to the base plate, achieve another special effect. The mixing process runs without varying pressure zone in the volume of mixing product. Separately driven multiple choppers can effectively intensify the mixing result in particular when liquid or paste components are added. During humidifying and granulating process of the products the chopper controls and regulates the granular spectrum and structure of the granules according to the product, chopper shape and time. The RMG system requires only small quantities of granulating liquid or pastes to obtain the required granulate structure. This reduces the amount of drying energy required.

Rapid Mixer Granulator is characterized by the Compact construction. Modern design and all the user and maintenance friendly attributes which form the ergonomically design aspects are essential for a wide range of application.

Salient features

- Rapid Mixer Granulator Machine Design is as per cGMP.

- It is available from 50 Litres capacity to 800 Litres capacity.

- Unique design with four arm mixing impeller with blade angle to pushing product radically outward.

- Automated high speed mixing and granulating process in single bowl.

- High Precision mixing and granulation with Short Batch Time.

- Problem free Cleaning and Residue Free of Discharge.

- Chopper blade designed to cuts lumps and make granules.

- Easy and Safety in operation.